Cabinet Vapour Blasting

Cabinet Vapour Blasting

Precision Surface Restoration for Smaller Components

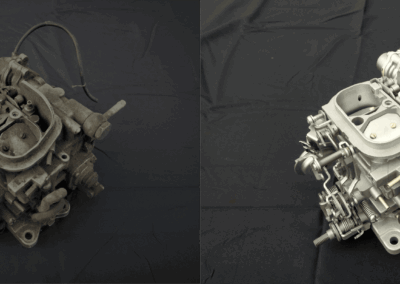

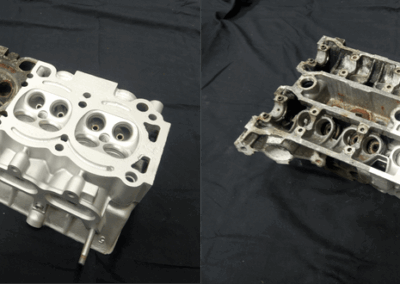

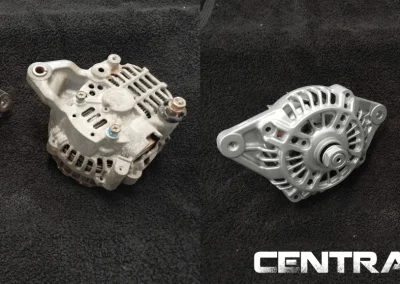

At Central Blast, our industry-leading Aquablast 1215 cabinet delivers professional, controlled blasting for smaller and intricate components. Designed to simultaneously blast and degrease, this cabinet achieves exceptional finished results across a wide range of metals and materials, providing a safe, non-toxic, and eco-friendly alternative to traditional blasting methods.

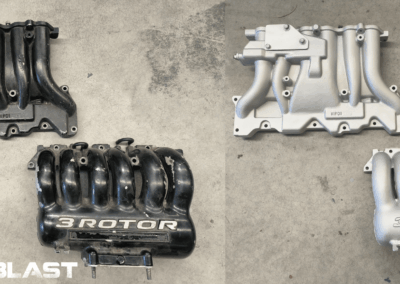

Perfect for automotive, marine, aircraft, and industrial components, cabinet blasting allows precise surface preparation without warping, bending, or damaging delicate parts. Whether you need restoration, cleaning, or pre-polish preparation, the Aquablast 1215 ensures a smooth, satin finish every time.

NZ’s Precision Cabinet Blasting Specialists

Also known as dustless blasting or wet abrasive blasting, our cabinet system uses controlled water and fine abrasive media to remove rust, grime, grease, paint, oxidation, and corrosion safely and efficiently. Unlike dry blasting, the Aquablast 1215 keeps dust to an absolute minimum while maintaining the integrity of the metal surface, leaving components restored and ready for assembly or coating.

With the ability to handle up to 150kg of components at once, the Aquablast 1215 is ideal for projects requiring both speed and precision. Its wet glass bead blasting technology ensures excellent results on all metals, including alloy, stainless steel, brass, copper, and more, without altering surface profiles.

Cabinet Vapour Blasting Applications

Automotive Components

-

Engine blocks and cylinder heads

-

Gears, housings, and manifolds

-

Alloy wheels and mags

-

Gearboxes and motorcycle parts

Marine & Recreational

-

Hull fittings, engine components, and accessories

-

Alloy and stainless steel parts

-

Brass, copper, and mixed metal restoration

Aircraft & Industrial

-

Gearbox internals

-

Aircraft components and fittings

-

Pre-polish preparation for metals of all types

Why Choose Cabinet Vapour Blasting?

Safe & Non-Toxic

Gentle, chemical-free, dustless blasting protects delicate components and operators.

Precision & Control

Controlled pressure and fine abrasive media ensure no warping or surface damage.

High-Quality Finish

Restores components to “like-new” condition with smooth satin finishes.

Versatile Metal Compatibility

Excellent results on alloy, stainless steel, brass, copper, and more.

Ready to Get Started?